FET-C

The FET-C Final Electrical Test station is the baseline model for the C series of automated production line test stations. With a very small facilities footprint and high-speed (2,000 parts per hour), unattended operation, this is truly an economical machine to operate.

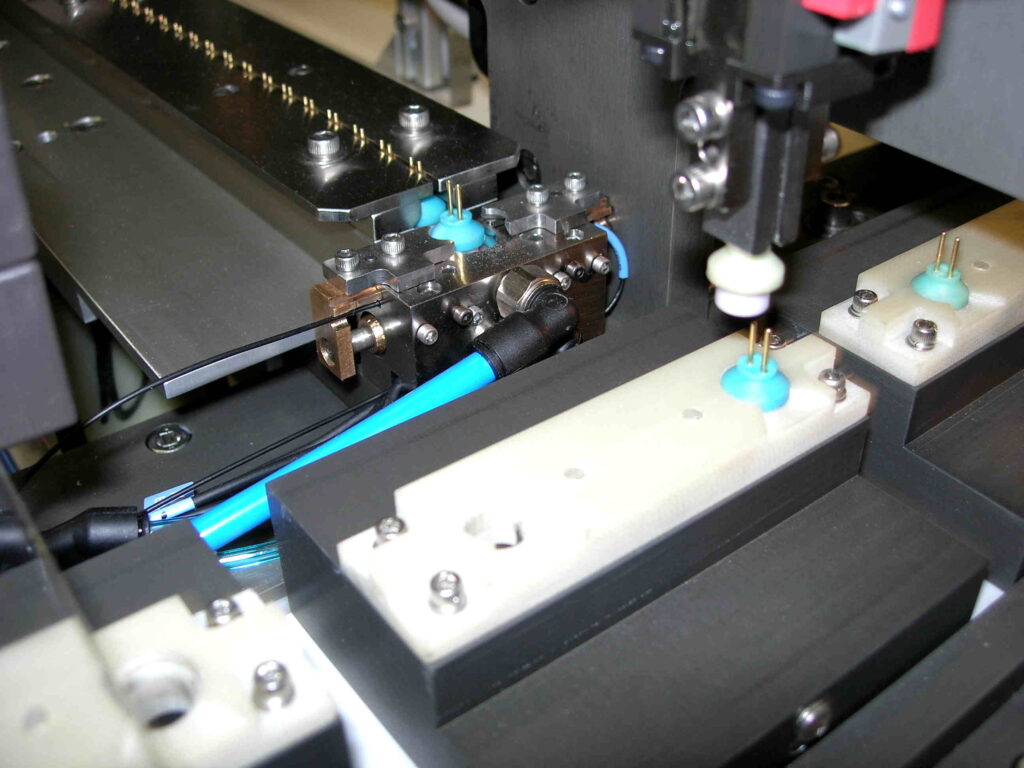

Airbag initiators to be tested (either Amphenol or exposed pin types) are loaded “loose” into a vibratory feed bowl. The initiators are then automatically aligned and loaded onto a precision timing-belt conveyor for testing.

The FET-C test station then performs a complete series of tests on each part; 4-wire (Kelvin) bridgewire resistance, thermal transient, series impedance and insulation resistance testing. A unique test parameters file allows pass/fail limits to be associated with individual part numbers, and all test results (both pass and fail) are archived to disk.

Defective parts are automatically removed to one of 8 user selectable reject bins. At the next station good parts are automatically ink-jet marked using a Videojet high-resolution printer. After moving to the next station all acceptable parts are placed into a large capacity acceptance bin. Correct part removal is verified with an optical detector.

Our signature operator/maintenance console provides full machine control for alignment and troubleshooting, allowing the technician to test all portions of the equipment. Bar-code input is standard, reducing operator error.

The precision vacuum pickup module may be specified with integrated height gage (LVDT transducer) or insulation resistance probes.

A set of grippers are included within the pickup module to maintain orientation of the part while waiting for pickup.

Downloads (PDF)